Combating compliance

Firstly, the definitions. In their 2012 Handbook of Research on Service-Oriented Systems and Non-Functional Properties: Future Directions, the authors, a mixture of academics, analysts and accountants, explain that, "Compliance generally refers to the conformance to a set of laws, regulations, policies, best practices, or service-level agreements."

"Compliance governance refers to the set of procedures, methodologies, and technologies put in place by a corporation to carry out, monitor, and manage compliance. Compliance governance is an important, expensive, and complex problem to deal with."

So what does it really mean? In my experience, there are two ways of looking at compliance. The negative view is that it’s a necessary evil, an expensive and bureaucratic barrier to getting things done and running an operationally efficient business.

There is another view though. For example, visiting the hospital is already an unpleasant experience for many, so what would you think if you were told that the ventilator that’s supporting your breathing had achieved a faster time-to-market because it didn’t have to go through numerous legislative checklists? All of a sudden, correctly implemented compliance moves to the forefront of product development and becomes a much more attractive prospect.

This second, and much more sustainable, way of looking at compliance portrays it as an opportunity, a chance to innovate and offer better products while breaking down the barriers-to-entry into new, previously unexplored markets.

The compliance process

During the battery and charger development process that we undertake at Accutronics, we take the design specification of a new product and begin to ask questions like, what is the purpose of the end-user product? What does it do? What is it capable of doing? This helps us to build a picture of the performance claims we’re making.

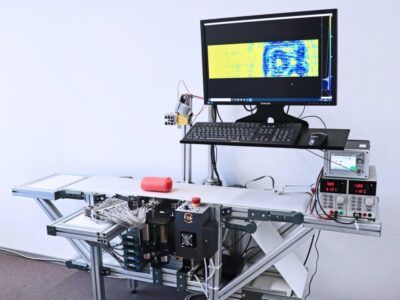

Once we have completed the specification and developed the product, we start the process of internal verification to prove these claims. This begins the process of laboratory testing. Because we have our own in-house testing facilities, we undertake the pre-certification testing to gather our own documented evidence. Some small and medium sized enterprises (SMEs) often lack the resources to staff and equip an in-house test (pre-certification) facility. We find that ours enables us to react quickly to changes and improvements, often within a few hours. Ultimately, this generates a cost effective competitive advantage, allowing us and our customers to punch above our weight against much larger businesses.

Once internal testing and verification is complete, the next stage is to send the battery or charger along with the relevant samples and supporting evidence, to be market certified by an industry regulated test laboratory. All of our off-the-shelf Entellion range is sent to be certified as a matter of course and for our custom solutions, we offer to project manage this certification process on behalf of our customers.

Global market access

In this age of globalisation, achieving compliance in one country or region is not enough. OEMs must design products to meet the various certification requirements of different markets throughout the world. One testing organisation, Underwriters Laboratories (UL), a global independent safety science company, uses the term Global Market Access to describe this task.

Other test laboratories with a global presence, such as Intertek, who provide quality and safety services to businesses and TÜV – one of the world’s leading technical service organisations, offer similar testing to international and regional standards. Accutronics works with our customers to select the most appropriate test laboratory based on customer preference, cost, testing location and availability.

All regions are broken down by mandatory and voluntary certification markings. Looking at just a few of the mandatory marks, we begin to see the sheer complexity involved in achieving access into more than just your local market.

Many countries are members of the CB (certified body) scheme. The national committee of each member country designates its own national certification body or bodies (NCB) who are responsible for recognising and issuing CB test certificates. While the International Electrotechnical Commission (IEC) CB scheme sets out to harmonise regional standards, permitting testing undertaken in one country to be mutually accepted in another, there remain some regional differences and the CB scheme is not universally recognised.

For example Europe uses CE and ATEX, Canada uses IC, the United States uses FCC and HAZLOC. Russia uses GOST-R, Australia and New Zealand use C-Tick and A-Tick. Argentina uses CNC, ANATEL in Brazil, SUBTEL in Chile and NOM and COFETEL in Mexico. In Asia, China uses CCC and CEL. Hong Kong uses EMSD, India uses S, ISI and WPC. Japan uses PSE and MIC. Korea uses KC, Malaysia uses ST and SIRIM, Singapore and Thailand use variations of Safety Mark and Taiwan uses BSMI. Middle East and Africa use variations of MoC.

To put that into context, these are just some of the 70+ certification marks in use that govern the basic compliance of various categories of new products and doesn’t include the numerous voluntary certifications.

The interesting thing to note is that while European and North American certification marks have been around for many decades, more recent certifications, especially in Asia, are often almost identical in content to existing European and North American ones.

Multiple marks exist, covering essentially the same requirements, to help countries and regions apply market control. Countries like China have traditionally played the role of the production workhorse for western innovation. However, with its rapid economic growth in recent years, China can begin to claw back control over future innovation, as well as using certification as a secondary revenue stream.

To bypass this legislative barrier, many western OEMs have been forced to setup permanent production facilities in China, spurring a gradual and much wider power-shift from West to East. It will be interesting to see how this affects the protection of intellectual property going forward.

Building relationships

With so much compliance based complexity, it can be difficult for smaller OEMs to compete. In our ongoing journey to reach multiple markets, Accutronics has sometimes experienced a lack of transparency.

One of the key ways we’ve found to overcome this complexity is to build a good working relationship with regulatory bodies and test laboratories. By establishing partnerships we can be sure that we are using the right paperwork, submitting the right evidence, meeting deadlines and staying up to date with the latest regulatory changes.

To give an example, complexity doesn’t just pose a challenge to Accutronics for battery and charger compliance, our customers also find it difficult to navigate the maze of outdated and obsolete legislation floating around on the Internet and in marketing literature. Therefore, by building these relationships we can stay ahead of the game, giving the most relevant advice to our customers and improving their offering.

In summary, overcoming the complex compliance requirements of battery and charger qualification is not just about re-engineering internal design, verification and testing processes; it is also about building sustainable long-term relationships with regulatory bodies and test laboratories.

About the author

Peter Inwood is Compliance Manager at Accutronics Ltd – www.accutronics.co.uk

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News