LED-based sensors for wearable fitness tracking products

More and more people are tracking their physical fitness with the aid of wearable gadgets and appropriate apps. Optical sensors are suitable for measuring pulse rates and oxygen saturation in blood. The technology has long been established in the medical sector and can now be transferred to consumer applications thanks to modern LED technologies.

Fig. 1: The "Quantified Self" movement — in short, self-knowledge through self-tracking with technology — is growing. Millions of people are using fitness trackers, and the numbers are increasing. With the aid of optical sensors, trendy armbands and smartwatches can measure pulse rate and oxygen saturation in the blood.

It all started with armbands that could record the number of paces a person took. Now, many activity trackers such as fitness armbands and smartwatches can also measure heart rate and other biometric values or monitor sleep quality. The new opportunities for tracking your own fitness levels have been enthusiastically embraced by many people, leading to a growing "Quantified Self" movement. Major players such as Samsung, Apple and Google are now entering this growing market with appropriate apps, smartwatches and smartphones.

Whereas pace counters use acceleration sensors, optical methods traditionally used in the medical sector for pulse and blood oxygen measurements are now finding their way into the consumer market. In the hospital environment, the sensors are mostly installed in ear or finger clips. In 2013, the Mio Alpha smartwatch was the first armband that could measure the pulse rate at the wrist using an optical sensor – a significant advance compared with the chest belt worn by athletes, which no one would enjoy wearing all day. Smartphones are also able to measure pulse rates on a finger. The first fitness armbands are now coming onto the market that enable you to measure the oxygen saturation in your blood simply by placing your finger on a screen. This feature is useful, for example, for people engaged in activities at high altitudes, such as mountain climbers, hang-gliders and glider pilots, and also for people with heart or lung problems.

Next: Optical measurement

Optical measurement methods

The principle on which the sensors measure pulse rate and oxygen saturation is called photoplethysmography (PPG), in other words the optical measurement of changes in the volume of blood in the blood vessels. The method makes use of the fact that the volume of blood transported in the arteries changes as the heart goes through its pumping cycle. The heart rhythmically expels blood (systole) and draws it in (diastole) in a constant cycle. This means that more blood flows through the arteries in the systolic phase, and less during the diastolic phase. By measuring the change in the volume of blood at a particular location on the body it is possible to derive the pulse rate from the periodicity of the measured signal.

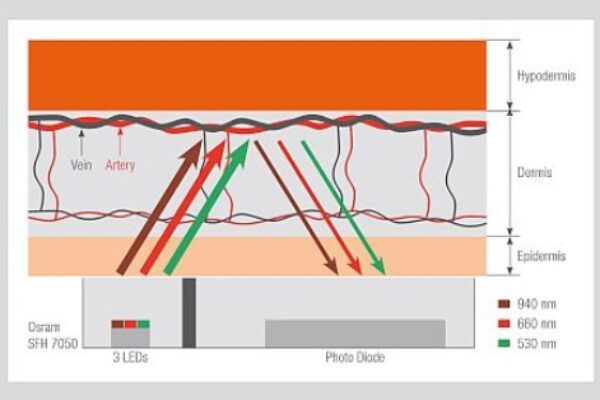

Fig. 2: The principle of reflective optical pulse measurements. Light emitted by the sensor penetrates the skin and tissue and is absorbed or reflected back to the detector. Because the volume of blood in the arteries changes with every beat of the heart, the amount of light absorbed and therefore the strength of the detector signal also changes. Green light provides the best results at the wrist, whereas red and infrared light is generally used on fingers.

Measurement of the volume of blood is based on the ability of the hemoglobin in the blood to absorb light (Fig. 2). The sensor, consisting of a light source and a detector arranged next to one another, is placed directly on the skin. The light emitted penetrates the skin, tissue and blood vessels and is absorbed, transmitted and reflected.

Next: how much light?

The amount of reflected light recorded by the detector changes according to the changing amount of blood flowing through the arteries (Fig. 3). The appropriate wavelength for this measurement depends on the part of the body where the measurement is taken. Green light provides the best results at the wrist, whereas red and infrared light is generally used on fingers.

Fig. 3: Production of the detector signal in a PPG measurement. The light directed at the skin (I0) is absorbed by venous blood and arterial blood or reflected back to the detector. The changing component of the signal corresponds to the amount of blood in the arteries pulsing in time with the heartbeat. The periodicity of this signal indicates the pulse rate. The ratio of the minimum and maximum detector signal values (photocurrent Imin/Imax) provides the basis for determining oxygen saturation of the blood.

The oxygen saturation of arterial blood can be determined if infrared light and red light are used to measure absorption. This method is known as pulse oximetry and is the only non-invasive method for determining oxygen saturation, in other words the only one that does not require a blood sample to be taken. Pulse oximetry makes use of the fact that blood low in oxygen and blood rich in oxygen absorb different amounts of light. Oxygen is transported in blood by means of the hemoglobin molecule (Hb). When it combines with oxygen to form oxyhemoglobin (HbO2) its absorption behavior changes (Fig. 4). The concentrations of the two hemoglobin molecules in blood (cHbO2 and cHb) indicate the oxygen saturation SpO2: SpO2= cHbO2/(cHbO2 + cHb).

Next: two types of light

Fig. 4: The absorption properties of hemoglobin (Hb), the pigment in blood, change as hemoglobin bonds with oxygen (oxyhemoglobin or HbO2). The oxygen saturation of blood can be determined by a PPG measurement with red and infrared light.

The concentration of a light-absorbent substance in an irradiated medium is a function of the degree of absorption. Two different wavelengths are used to obtain a reliable indication of cHbO2 and cHb from PPG measurements [2]. Red light with a wavelength of 660 nanometers (nm) and infrared light with a wavelength of 940 nm are ideal here because the difference in the absorption properties of the two types of hemoglobin molecule (Hb and HbO2) is greatest with these wavelengths (Fig. 4). To determine the oxygen saturation of arterial blood we need to look at the absorption of the pulsing signal component (Fig. 3). Oxygen saturation (SpO2) can be expressed as a function of the ratio between minimum and maximum detector signals (Imin/Imax) for the relevant wavelength [2].

Next: What’s the sensor?

Components for measuring pulse rate and oxygen saturation of blood (contd.)

Only with the development of thin-film chip technology has it been possible to produce highly efficient LEDs with narrow spectral bandwidths of around 30 nm. The technology also ensures high system efficiency because thin-film LEDs emit almost all of their light from the top, with the result that virtually all of it can be used for the application. The design must also ensure that the wavelength remains stable throughout the measurement despite the temperature rise at the chip. In addition to good thermal stability of the LEDs, short pulses are a good way to keep the wavelength constant. Pulse lengths of less than 0.3 milliseconds with a repeat rate of around two milliseconds are suitable. The choice of wavelength depends on the measurement planned. For sensors worn on the wrist green LEDs with a wavelength of around 530 nm are suitable; for finger sensors red (660 nm) or infrared (940 nm) light is usually used. The LEDs are available in various discrete versions and are therefore suitable for different designs and applications. One wavelength is sufficient for pulse sensors, whereas red and infrared light is used alternately for measuring oxygen saturation.

For the detector, the crucial requirements include high linearity, excellent sensitivity and a good signal-to-noise ratio. Linearity is particularly important for measuring blood oxygen levels because the absolute photocurrent values Imin and Imax have to be measured very accurately. Large-area photodiodes with low dark current are suitable, for example SFH 2400[a] or SFH 2430[b], the version with an ambient light filter (see below). Photodiodes also offer rapid switching times so they can resolve the required short LED pulses.

Integrated sensors such as the SFH 7050[c] are a particularly compact solution. This multichip sensor contains three LEDs and one photodiode and has been designed specifically for pulse and oxygen saturation measurements in wearables and smartphones. Highly efficient LEDs in thin-film technology with narrow emission bandwidths in green (530 nm), red (660 nm) and infrared (940 nm) enable pulse rates to be measured at the wrist and oxygen saturation to be measured on a finger. An integrated light barrier prevents optical crosstalk from the LEDs to the photodiode. Depending on the application, the LEDs can be either operated individually or controlled in turn.

Fig. 5: The integrated SFH 7050 sensor has been designed specifically for PPG and pulse oximetry applications in wearables and smartphones. It features three LED emitters and one photodiode in a compact unit.

The infrared LED in SFH 7050 can also be used in combination with the receiver as a proximity sensor to start or stop the measurement automatically as soon as the sensor touches or moves away from the skin. Chipsets for PPG and pulse oximetry measurements in medical applications are available on the market for controlling the LEDs and digitizing the detector signal. A good example with an excellent digitizing resolution (22 bit) is the TI AFE 4403 from Texas Instruments[d].

Next: Dealing with ambient light

Sensor design

As with all sensors, signal quality is one of the most important considerations for the design of an optical sensor for pulse rate and oxygen saturation measurements. The complete detector signal comprises a very large constant (DC) component and a small variable (AC) component – corresponding to pulsing arterial blood (Fig. 3).

Measurements with a wavelength of 530 nm and an LED current of eight milliamps on the wrist of a fair-skinned person, for example, will produce an AC/DC ratio of around 0.00035 [1]. For a dark-skinned person this value will be lower, and on a finger it will be around ten times higher. This extremely small AC signal as a proportion of the overall signal is a challenge for the digitization process – particularly if blood oxygen levels are to be measured. In this case, the entire signal has to be digitized so that the resolution of the AC component and its minimum and maximum values (Imin and Imax) is very high. In practice, this means that the overall signal requires a resolution of at least 16 bits [1]. If only heart rate has to be measured, then it is just the periodicity of the signal that is of interest, not the absolute signal level. In this case, the constant component can be suppressed with a bandpass filter and the remaining AC component amplified for the AC/DC converter. Also important for achieving high resolution for the minimum and maximum values of the photocurrent are closely spaced measurements. Typical sampling rates are between 25 and 500 Hertz per channel with LED pulse lengths of half a millisecond to five microseconds.

Another factor is the ambient light. It can reach the receiver even if the sensor is placed right on the skin because infrared light penetrates deep into the skin and is dispersed there. Ambient light adversely affects the signal-to-noise ratio and should be suppressed as far as possible, for example by good contact between the sensor and the body or by special ambient light filters on the detector. Such filters shift the maximum sensitivity of the detector from the infrared spectrum to the visible spectrum, for example to 570 nm in the case of photodiode SFH 2430. They are ideal therefore for use with green LEDs. A method commonly used to eliminate ambient light effects in the detector signal is to take measurements with and without LEDs and then take the difference between the two signals. Chipsets such as TI AFE 4403 also emit an appropriate dark signal for this purpose.

Next: And rest

Summary

As the Quantified Self movement continues to grow, optical sensors for medical applications are beginning to penetrate the consumer electronics sector, particularly in fitness armbands, smartwatches and smartphones. This has been made possible not least by the development of high-efficiency LEDs with excellent spectral purity. Integrated optical sensors for measuring pulse rate and oxygen saturation represent a further stage of development in this growing market.

The authors

Dr. Jörg Heerlein studied Electrical Engineering, majoring in Microelectronics, at the University of Duisburg. In 1999 he gained his doctorate for research into Power Laser Diodes at the University of Ulm. He is currently Head of Product Marketing for Infrared Components in the Industry and Distribution Division at OSRAM Opto Semiconductors GmbH in Regensburg.

Dr. Tilman Rügheimer studied Physics, majoring in solid-state physics, at the University of Erlangen-Nuremberg, where he also gained his doctorate in detector physics. He has been working for Osram Opto Semiconductors GmbH in Regensburg since 2010, currently as the product manager for Biomonitoring Sensors.

References

[1] Application document "SFH 7050 – Photoplethysmography Sensor", Osram Opto Semiconductors, 2014

[2] J. G. Webster, "Design of Pulse Oximeters", Series in Medical Physics and Biomedical Engineering, Taylor & Francis, New York, USA, 1997.

Components mentioned in this article

[a] Osram SFH 2400 SMT PIN diode

[b] Osram SFH 2430 SMT PIN diode

[c] Osram SFH 7050 Integrated bio-sensor

[d] Texas Instruments TI AFE 4403 Ultra-Small, Integrated Analog Front-End for Heart Rate Monitors and Low-Cost Pulse Oximeters

Osram, with its headquarters in Munich, is one of the two leading lighting manufacturers in the world. Its subsidiary, OSRAM Opto Semiconductors GmbH in Regensburg (Germany), offers its customers solutions based on semiconductor technology for lighting, sensor and visualization applications. Osram Opto Semiconductors has production sites in Regensburg (Germany), Penang (Malaysia) and Wuxi (China). Its headquarters for North America is in Sunnyvale (USA). Its headquarters for the Asia region is in Hong Kong. Osram Opto Semiconductors also has sales offices throughout the world. For more information go to www.osram-os.com.

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News