3D sub-surface imaging tackles landmine detection

The three-year GBP 100,000 research project lead by Dr Manuchehr Soleimani at the Engineering Tomography Lab (ETL) of the University of Bath aims to provide technology that can differentiate between images of plastic and metallic elements within a single explosive device, at depths of up to 10cm underground on varied terrain.

Dr. Soleimani’s lab was awarded funding from Sir Bobby Charlton’s charity Find A Better Way (FABW) via a competition organised by the Engineering and Physical Sciences Research Council (EPSRC).

While ground-penetrating detection techniques such as radar or metal detectors may be more mature, anti-personnel landmines manufacturers have moved to using plastic instead of metal, both for economical and stealth reasons, which makes their detection increasingly difficult.

Hence the need to detect beyond metals. This has been the focus of Dr Soleimani’s recent publications on electrical and electromagnetic tomographic imaging and volumetric image reconstruction. In two separate papers, "Planar array 3D electrical capacitive tomography", and "Planar magnetic induction tomography for 3D near subsurface imaging", Soleimani showed promising results which he says could be exploited to design new advanced multi-modal capacitive/inductive camera technology.

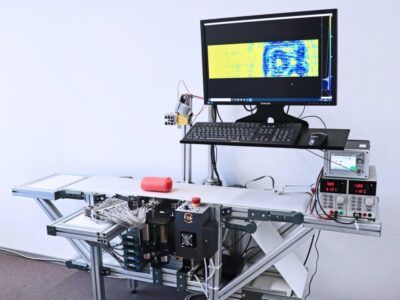

For the Electrical Capacitance Tomography (ECT) part, his team used a set of 12 copper electrodes arranged in a 4×3 matrix array (250 by 250mm in total, 4mm thin) and a 12-channel capacitance measurement instrument to image the dielectric permittivity properties of objects placed in front of the sensor array. He was able to image dielectric solids at a depth of just over half the full sensor array’s length.

For the Magnetic Induction Tomography (MIT) part, inductive coils and eddy currents were used to map the passive electromagnetic properties of the objects to be detected, in 3D. Here the sensors (16 air-core cylindrical coils, each 4cm in diameter) were placed in a circular shape with their axes perpendicular to the plate. 3D image reconstruction was performed based on the analysis of sequential coil excitations and responses.

"We are looking at integrating these two types of sensors, using patent pending techniques, so we could get 3D imaging information from one type and get the reminder information from the other to complete the picture" told us Soleimani during a phone interview.

"The idea is to use both imaging techniques across a range of frequencies and get a spectroscopic signature of the materials being imaged", he said.

"In effect, we could build a library of material signatures so the imaging of buried dielectric materials could yield their precise compositions. This could be associated with a matching table of known landmines to speed their identification, based on their shape and composition", he explained.

Further work will be required to profile the surrounding ground properties in which landmines can be buried, so the sensors can better distinguish the explosive devices, but Soleimani is rather optimistic, saying his team has already obtained encouraging results using crude models.

Then will remain the typical trade-off between sensor array size, complexity, and imaging speed. One would want to cover a reasonable area in one scan, probably with sensor arrays mounted on a rover robot arm.

Visit the ETL of the University of Bath at https://www.bath.ac.uk/elec-eng

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News