Giving devices the green light for time sensitive networking

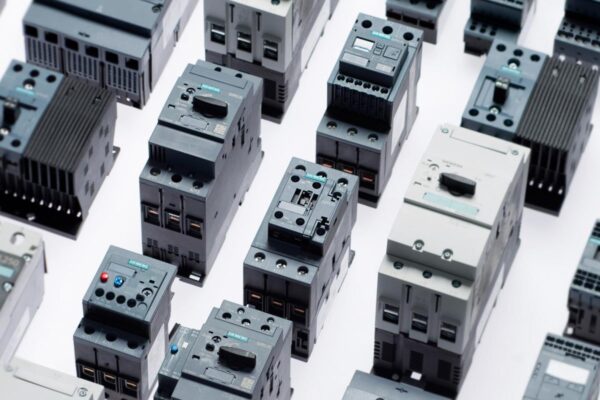

That shift encapsulates why companies like Schneider Electric and Bosch support an extension of Ethernet called time sensitive networking in factories. Now the Avnu Alliance, a technology trade group, has released tests to certify that industrial devices using the standard can all work together on the same network.

Time sensitive networking is a standard that lets industrial control or smoke detection systems, which cannot afford even the slightest delay, to share the same network that handle data from cameras or sensors embedded in robots, which can move more leisurely. The standard exists to prevent delays, which could cost thousands or millions of dollars in damage or lost productivity.

Time sensitive networking can complement other types of industrial Ethernet like EtherCat and replace proprietary standards like HART and CAN. But it can reduce complex and costly cabling in factories. Cisco and Broadcom have started selling switches that follow the standard, which supports low jitter and low latency communications.

Avnu’s conformance test targets time synchronization, which keeps every clock in an industrial control network on the same time to within less than a microsecond. Todd Walter, who leads the Avnu Alliance’s industrial division, said that the time synchronization tests came first because they are “foundational” for measurement and factory control.

To pass the test, electrical engineers need to follow hundreds of pages of requirements drafted by the Avnu Alliance, which consists of companies like Rockwell Automation, National Instruments, and others. The group takes interoperability seriously because factory robots and the connected sensors that monitor them are built with parts from multiple suppliers.

The International Federation of Robotics estimates that 290,000 factory robots were installed worldwide last year and predicts the number to grow to 414,000 in 2019. General Motors hooked its robots to the internet so that it could order parts to repair them when they start to wear out and not keep lots of replacement parts in storage.

“Automation is a central competitive factor for traditional manufacturing groups, but is also becoming increasingly important for small and medium-sized enterprises,” said Joe Gemma, the federation’s president, in a statement. The federation pointed to a growing market for modular robots that can be sold at low prices.

Other major parts of the standard include traffic shaping, which requires all devices to process and forward packets of information between each other in the same way. These devices also must take communications paths to save the most bandwidth and safeguard against faults. Walters said that tests for these standards are in the pipeline.

The Avnu Alliance has also partnered with the Industrial Internet Consortium, which has codified security frameworks for factory equipment. It also works with the OPC Foundation, which sets connectivity standards for industrial and process control systems, with an eye toward crafting tests for application layer software.

This article originally appeared in Electronic Design – www.electronicdesign.com

Related articles:

EtherCat opens to heterogeneous networks with TSN features

European test house for AVB/TSN standards opens doors

Innovasic demonstrates TSN-ready deterministic Ethernet for automotive

Automotive Ethernet needed for adaptive headlights, says Porsche

Ethernet to redefine E/E architectures

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News

If you enjoyed this article, you will like the following ones: don't miss them by subscribing to :

eeNews on Google News